PLA RFID Cards represent a revolutionary step forward in sustainable technology. Made from Polylactic Acid (PLA)—a bioplastic derived from renewable resources like corn starch or sugarcane—these cards offer a powerful alternative to traditional petroleum-based PVC cards.

SGS certificate

Biobased & Renewable: Sourced from annually renewable plants, reducing dependence on fossil fuels.

Reduced Carbon Footprint: The manufacturing process of PLA generates significantly fewer greenhouse gases compared to PVC.

Industrial Compostable: Under the right conditions (high temperature and humidity in a commercial facility), the card body can break down into compost.

Full RFID Functionality: Compatible with LF (125kHz) and HF (13.56MHz) RFID inlays, offering the same performance as conventional cards.

Smooth Printing Surface: Excellent for high-quality printing with eco-friendly inks, perfect for branding your sustainable initiative.

OEM/ODM Services: Customized designs, sizes, thicknesses

Personalized Customization: UV printing, embossing, magnetic stripes, RFID embedding, barcodes, QR codes, etc.

Key Features

Made from Polylactic Acid (PLA), a biodegradable and compostable bioplastic derived from renewable resources (e.g., corn starch, sugarcane, or cassava). Significantly reduces reliance on petroleum-based plastics (like PVC) and lowers carbon footprint.

Advantages

Eco-Friendly Material

Biodegradability & Sustainability

Safety & Non-Toxicity

Versatile Applications - Single-Use or Reusable

| Dimensions | 85.5*54mm (customizable size and shape |

| Protocol | ISO14443A、ISO15693、ISO18000 |

Chips | NXP series: NTAG, Mifare, Mifare(Duox), Desfire, Ultralight, UCODE, ICODE |

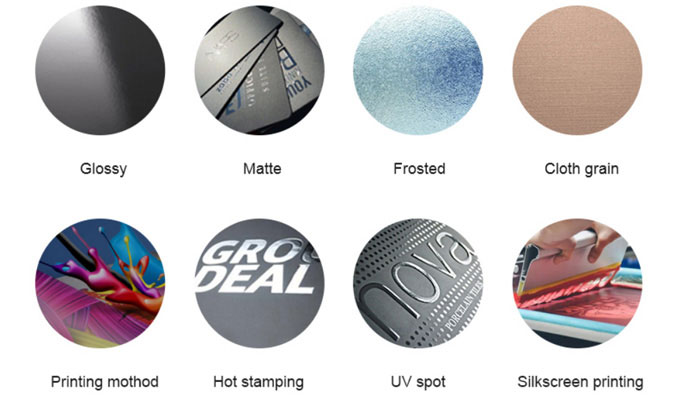

| Card Surface | Glossy, matte, frosted, epoxy (single or double sided), brushed (single or double sided) |

| Materials | PVC, PLA, PETG, PET, TESLIN, wood, bamboo, RPVC, paper, etc |

Operating frequency | 13.56MHZ |

Read/write distance | 2.5-8cm |

Data retention | 10 years |

Erase/write times | 100,000 times |

| Printing | Silk screen printing, offset printing, digital printing, anti-counterfeiting printing, UV printing |

Coding process | Inkjet code, laser code, flat code, embossed code, bar code, QR code |